Cork tiles are manufactured from granulated cork of selected quality, then compressed and baked, causing the natural resins and added binders to flow and form a firmly bonded homogeneous block from which tiles of varying size/thickness are cut.

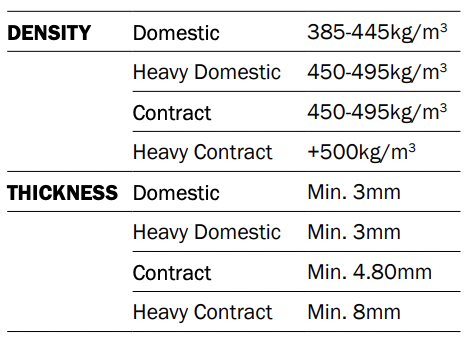

They are normally described according to density and thickness. Specifiers should consult manufacturers for individual requirements.

Tiles are normally available in a standard size of 300×300mm (or 305×305mm) with other sizes to special order, and in thicknesses from 3mm (1/8in) to 8mm (5/16in), although 4.8mm (3/16in) and 6.4mm (1/4in) are most generally used. Cork tiles have a warm and attractive natural finish when appropriately maintained.

They can also be supplied pre-finished with either wax, urethane, polymer or bonded vinyl coatings. They are hard-wearing, quiet underfoot and resistant to damage from dilute acids and most common chemicals.

Tiles vary in colour and are described as light, medium or dark, ranging from pale straw to a very dark brown

Some variation within each category shade is inevitable and the majority are produced in light and medium tones. Bleaching from strong sunlight can occur after installation.

Cork is only suitable for high traffic areas if selected from:

If not pre-finished with either a vinyl bonded surface or acrylated urethane, then the cork tile joints should be lightly sanded with a fine sandpaper to remove any ‘lipping’, any adhesive or dirt removed and the surface brushed clean. Final surface application of a minimum of three coats of polyurethane or oleo coatings should be applied. Due to the varying porosity of cork, more than three coats may be required to achieve the required surface finish.

Application of cork tiles is normally carried out with rubber/resin emulsion adhesive for thickness up to 4.8mm. For 6.4mm and 8mm thickness, a gum spirit adhesive is used – on occasion with the additional use of steel pins, or a solvent-based adhesive to manufacturers’ recommendations.

Cork tiles with a PVC backing must be bonded with an adhesive approved by the manufacturer. The tiles have sufficient flexibility to allow application over suspended timber floors, subject to the substrate being correctly prepared to eliminate movement at board joints. PVC-backed tiles are not recommended for installation over UFH systems.

Cork can be used in almost any situation by selection of a suitable density, thickness and surface finish. The manufacturers will provide advice on the selection and specification.

For more information about different types of resilient flooring, consult the CFA Guide to Contract Flooring.